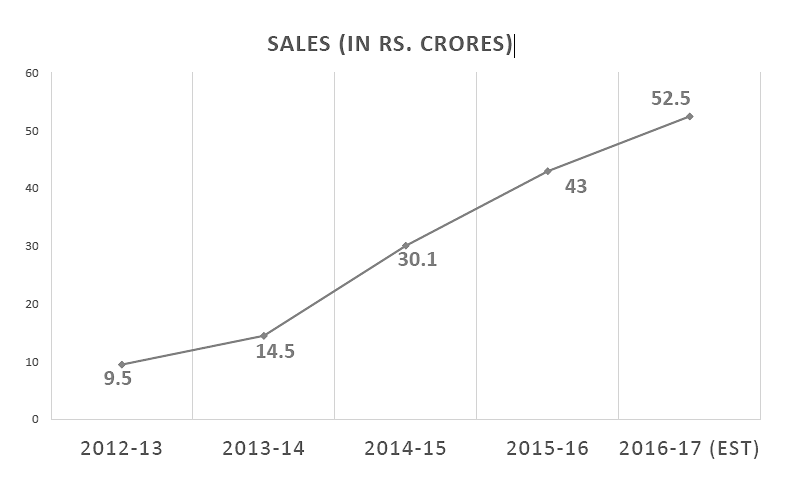

Grown 5 folds since 2012 – A CAGR OF 52%

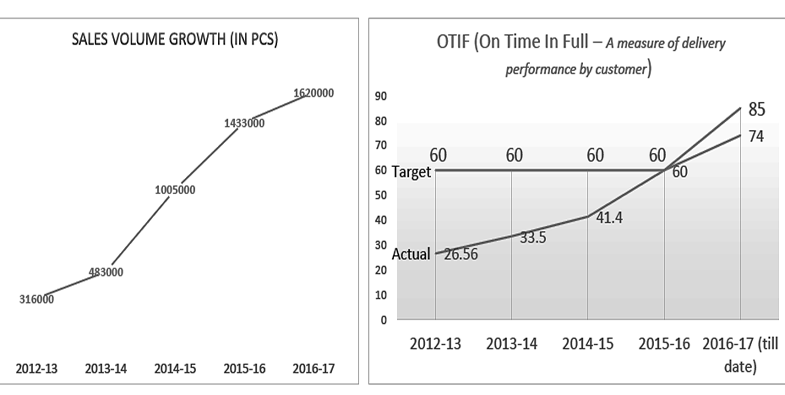

Delivery performance constantly improving amidst rapid growth

Delivery performance measures the timeliness of delivery. In terms of quantity supplied, Praveen has been supplying over 125% of the scheduled quantity month on month.

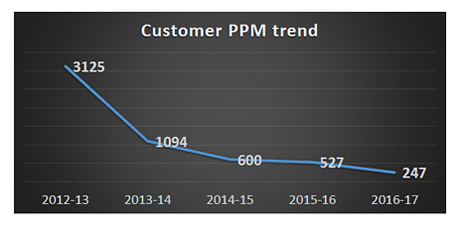

Quality Performance

Despite a tremendous increase in volume and new products, PEI has consistently reduced PPM through a systematic approach.

Factors Contributing to Consistent Performance

1. Robust production & Quality practices

- Q-Gates, to contain problems reaching the customer (and provide an improvement opportunity)

- Immediate response to any internal or customer problems -through Gemba & whats-app group.

- Detailed analysis of repeated quality problems & Improved problem solving capability.

- 3G Approach - Monitoring Customer Rejection trend, In-house rejection trend, Kaizen & Poko-Yoke trend.

- Active participation in customer initiatives to drive quality.

- Highly equipedWelding infrastructure & practices.

- Employee involvement & participation

- Constant training to upgrade the team’s skills

- Cell Concept Special Vehicle Parts that eases planning & co-ordination.

- Supermarket for runner items.

- SMED

3. Monitoring & control systems

- One Page Report -highlights problem areas for quality improvement.

- 3G Details to keep a tab on effectiveness of initiatives under taken.

4. Value engineering & cost savings

5. TPH (Tooling, Painting , Handling) improvements to ensure quality & delivery

- Tooling - Tool Up Project Under progress, NTTF Training & the main objective is to concentrate on tools for critical parts and extending tool life.

- Painting - In house Powder Coating to reduce delivery time & aesthetic issues and with best in class technology we want to introduce (NO HANDS to FG CONCEPT)

- Handling – Dedicated Trolley to avoid transit damages.

Vision - 2020

- To achieve a turnover of Rs. 100 crores withOTIF over 90% and at less than 100 PPM.

- To supply assembly components –leveraging strengths like large space availability.

- To introduce automationin all key areas possible -automated loading/ unloading in press shop, conveyors for material movement, automated powder coating set-up etc.,

- To be a one-stop shop for all sheet metal parts development.